FLUID PURFICATION SYSTEMS

FPS - HIGH VACUUM

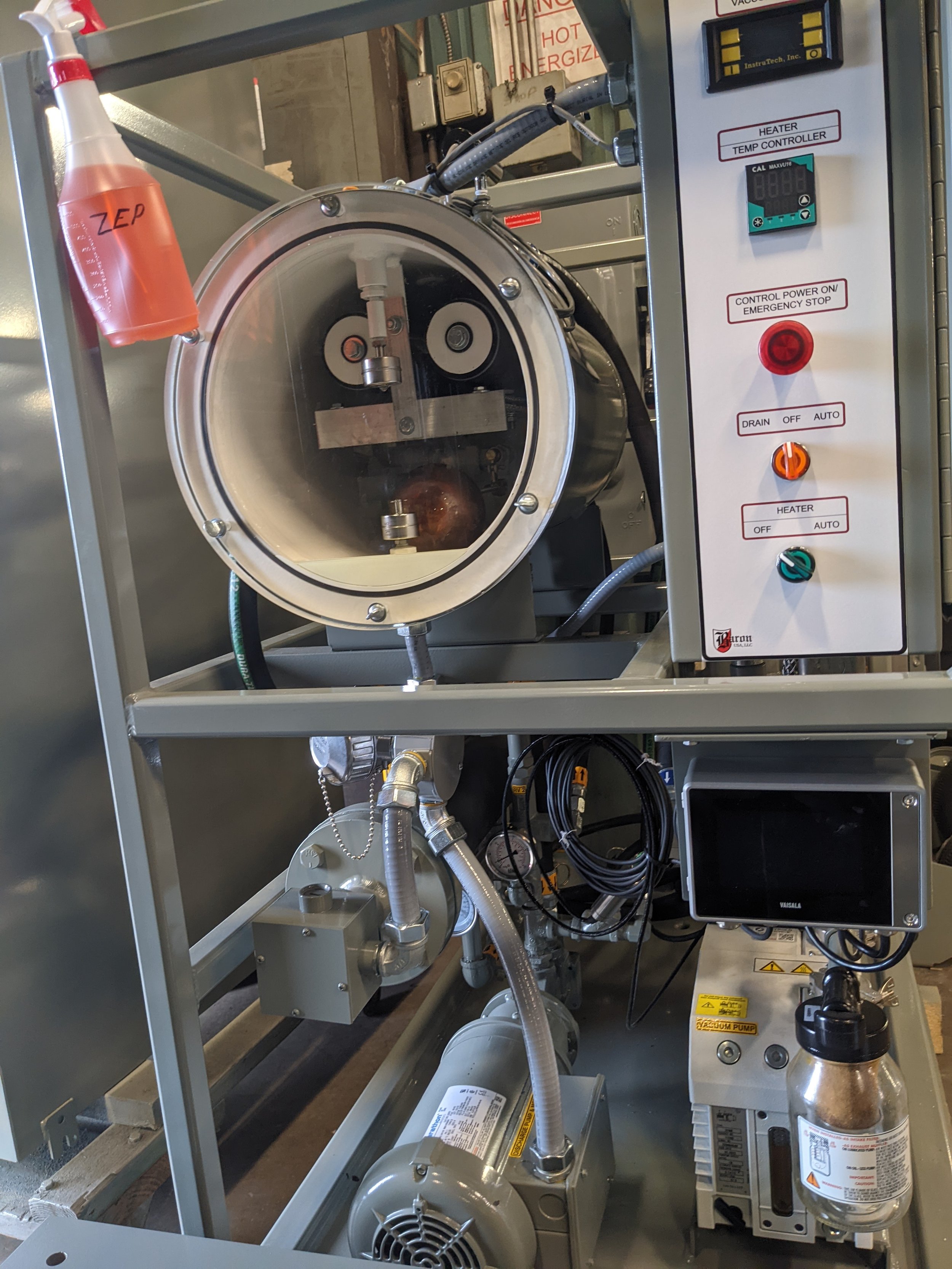

DESCRIPTION: Designed to process and maximize dielectric strength in electrical insulating liquids - including mineral oil, natural esters, synthetic esters, silicone oil and LFH’s (less flammable hydrocarbons) - used in transformers, tap changers, circuit breakers, and other oil-filled electrical devices.

CONTAMINANTS REMOVED:

CLASS II LIQUIDS: Contain excessive particulate, moisture, and dissolved gases. A basic high vacuum purifier will remove all three of these and return the oil to within specification.

CLASS III LIQUIDS: Contain products of oxidation like acids and sludge that affect neutralization number, color, interfacial tension and power factor. If these are present, the addition of an optional fullers earth reclamation filter is necessary for their removal.

FLOW RATE AND STANDARD FEATURES:

· 75-USgph nominal – adjustable from 0-100%

· Two stage, oil-sealed rotary vane vacuum pump with typical operating vacuum range < 5 Torr.

· Epoxy coated two-stage vacuum chamber with clear cover to allow observation of the degassing/dehydration process.

· Positive-displacement direct-driven discharge pump.

· 6-kW electric oil heater capable of raising the oil temperature by up to 70 °F per pass.

· Large particle capacity outlet filter with differential pressure gauge to indicate element change out.

· Viton and Teflon seals throughout.

· 10’ inlet and discharge oil hoses.

PORTABILITY AND ACCESSORIES: The standard system comes on castors but is also available in a small box trailer for servicing LTC’s, OCB’s and other small oil-filled field devices. Options include inlet pump for longer or uphill suction lines, ppm water-in-oil hygrometer, totalizing meters, and more.

Click the Fluid Purification System, FPS - High Vacuum Flyer to download a single-page flyer.